English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

Products

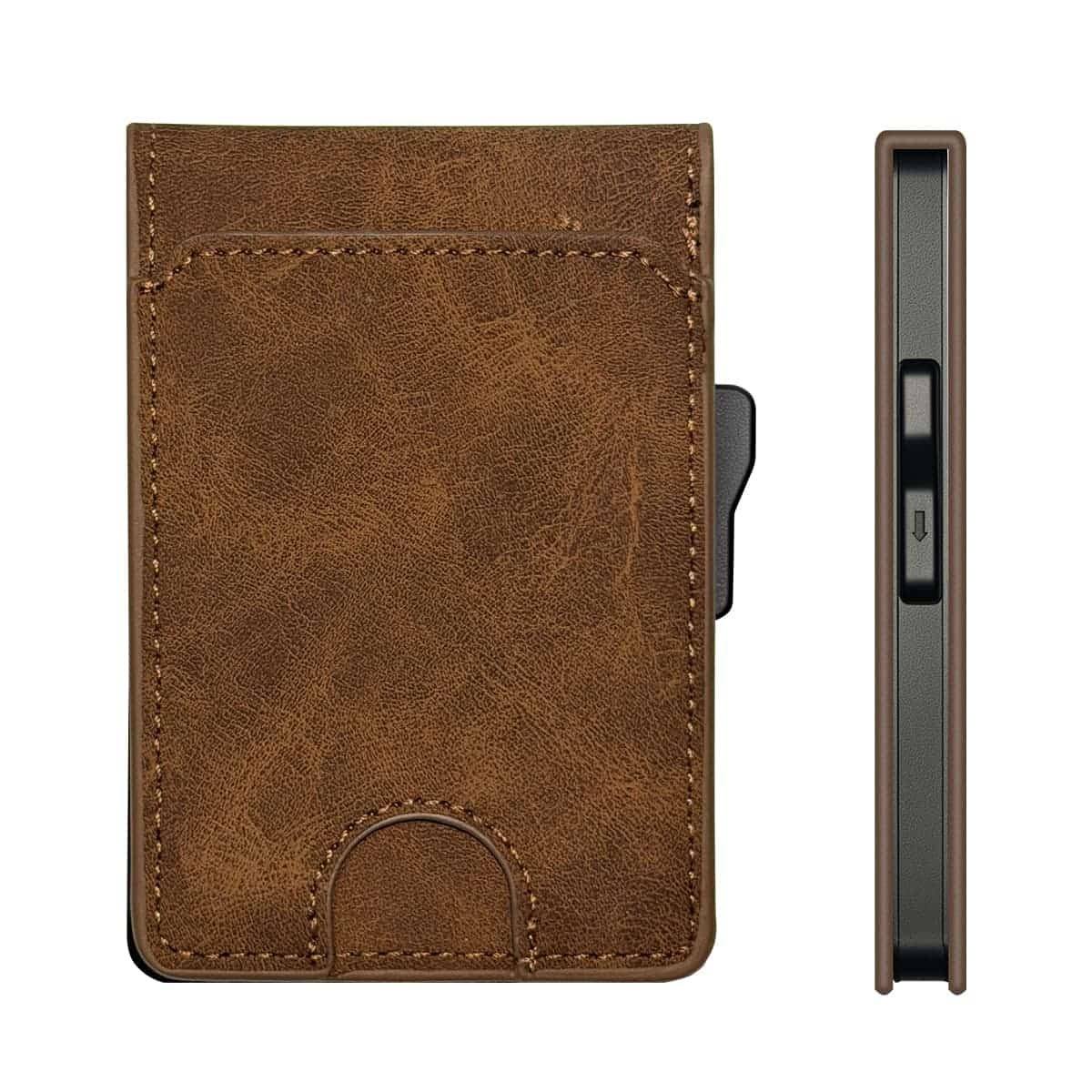

Sheet Metal Laser Cutting

You can rest assured to buy Sheet Metal Laser Cutting from our factory and we will offer you the best after-sale service and timely delivery.

Send Inquiry

Product Description

You can rest assured to buy Sheet Metal Laser Cutting from our factory and we will offer you the best after-sale service and timely delivery. Sheet metal shape development processing usually adopts the following methods: line drawing milling, wire cutting, plasma cutting, oxyacetylene flame cutting, die stamping, high pressure water cutting and CO2 laser cutting. Various cutting and blanking methods have their advantages and disadvantages. Accuracy, speed, and cost all vary. It has a certain scope of application in industrial production. Choosing the most convenient and widely applicable processing method is the task faced by the manufacture of liquid rocket engine sheet metal parts.

Product Details

Hot Tags: Sheet Metal Laser Cutting, China, Manufacturers, Suppliers, Factory, Customized, Advanced, Latest Selling, Buy, Price

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy