English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

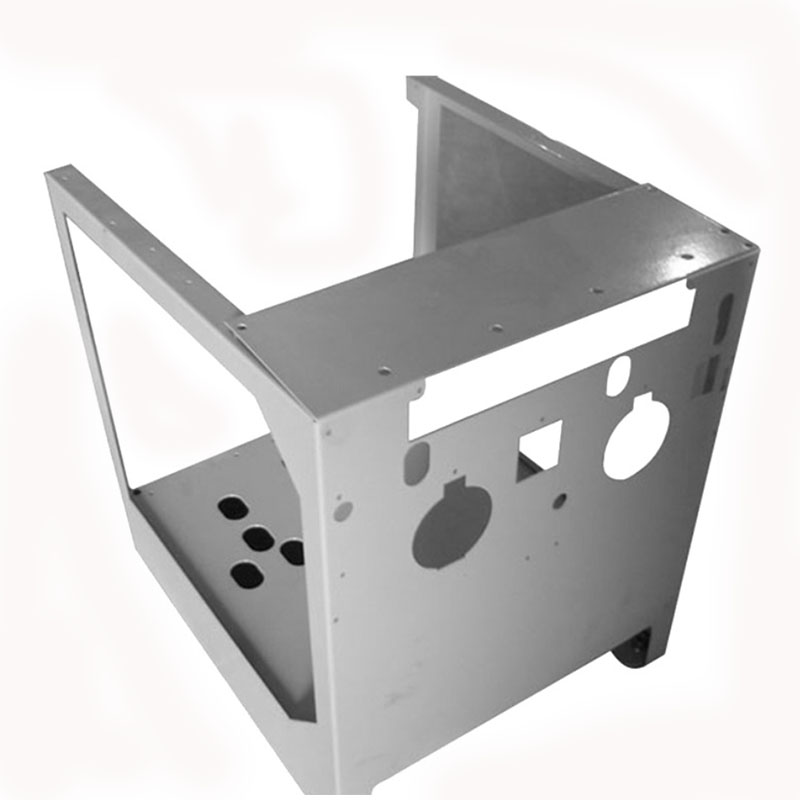

CNC Laser Cutting Processing

Send Inquiry

CNC laser cutting is mainly used for cutting metal. In addition to cutting such hard materials, different laser technologies can also cut materials such as cloth, glass and ceramics. The working principle of laser cutting is to use the reflector to control the laser beam to cut. Handle material. The reflector emits the beam from the laser, and then focuses it by a special lens to form a high-energy-density beam, and then processes the surface of the material.

Buy CNC Laser Cutting Processing which is of high quality directly with low price. Combining numerical control technology, advanced optical system and high-precision and automatic T-piece positioning, it integrates automatic nesting, cutting process database, remote diagnosis and remote control, and combines laser-cut functional parts with other processing methods to make Multi-functional processing machines such as laser punching machines are more in line with the complex processing and efficient needs of factories. It combines the multi-functionality of laser cutting and the high-speed and high-efficiency characteristics of other processing forms. It can complete cutting, punching, marking, and scribing at the same time. , Forming, etc.

Product Details