English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

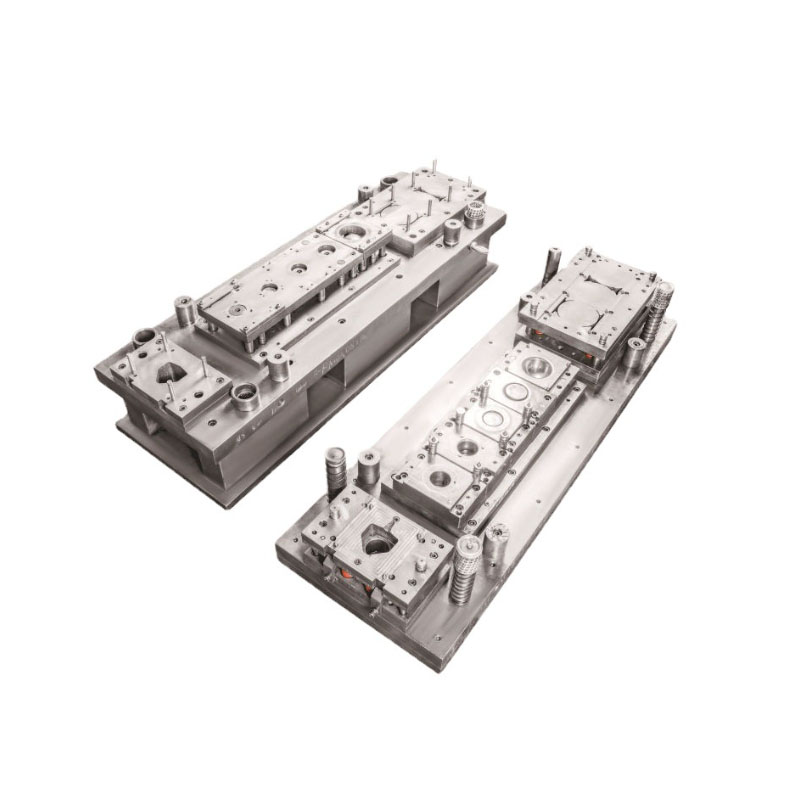

Metal Mold Stamping Parts

Send Inquiry

The materials of metal mold stamping parts include steel, hard alloy, steel bonded hard alloy, zinc-based alloy, low melting point alloy, aluminum bronze, polymer material and so on. At present, most of the materials used to manufacture stamping dies are mainly steel. The types of commonly used die working parts materials are: carbon tool steel, low alloy tool steel, high carbon high chromium or medium chromium tool steel, medium carbon alloy steel, high speed Steel, base steel and cemented carbide, steel-bonded carbide.

1. Stamping performance required for stamping materials of precision stamping parts:

1. Stamping materials should be easy to obtain high-quality and high-precision precision stamping parts, which is convenient for production and processing.

2. The ultimate deformation degree and the total ultimate deformation degree of a stamping process of stamping materials should be large enough to improve production efficiency.

3. The loss and wear of stamping materials on precision stamping parts and precision stamping dies should be low, and it is not easy to produce waste products, which is convenient for increasing production.

Second, the stamping materials of precision stamping parts should meet the process requirements:

1. The thickness tolerance of stamping materials should comply with national standards: different die clearances are suitable for materials of different thicknesses. If the thickness tolerance of materials is too large, it will not only directly affect the quality of punching parts, but may also cause damage to dies or presses.2. The stamping material has a high surface quality: the surface of the stamping material is clean and smooth, without defects such as scale, cracks, rust spots, scratches, and delamination. Materials with good surface conditions are not easy to break during processing, and it is not easy to scratch the mold, and the surface quality of the obtained stamping parts is also good.

3. The stamping material should have good plasticity: the stamping material should have high elongation and area shrinkage, low yield and high tensile strength, high plasticity, and a large degree of deformation, which is conducive to The stability of the stamping process and the uniformity of deformation improve the dimensional accuracy of precision stamping parts.

4. Stamping materials should have good adaptability to mechanical joints and further processing (such as welding, polishing, etc.), and should not damage mechanical equipment.

The stamping material of precision stamping parts is related to the performance and quality of stamping parts. The selection of stamping materials needs to meet the above relevant conditions and meet the production requirements.

Product Details